Glashütte Original is one of the few brands producing its dials in-house and under one roof thanks to the new dial manufactory opened in June 2025

The dial is the face of a timepiece and often the first element to capture our attention. In many cases, our decision to purchase a watch is shaped by the appeal of its dial.

Far more than a simple display, the dial is the result of intricate craftsmanship. Its creation involves numerous specialised steps, demanding exceptional precision and refined skill.

Glashütte Original is one of the few manufacturers capable of producing its dials entirely in-house, combining traditional techniques with industrial precision.

With the opening of its new dial manufactory in Glashütte in June 2025, the brand has consolidated key operations into a single, state-of-the-art facility. From the initial production of blanks to the final inspection, each stage is now carried out on site.

This comprehensive integration enables tighter process control, improved tolerances, and greater consistency across the diverse array of dial types produced.

Let’s take a closer look at the essential steps that bring each dial to life.

Materials and dial blanks

The process begins with the careful choice of base material, determined by the desired colour, finish, and structural requirements of the dial. Brass and German silver are used most frequently, while sterling silver, bronze, and gold are reserved for specific, exclusive models.

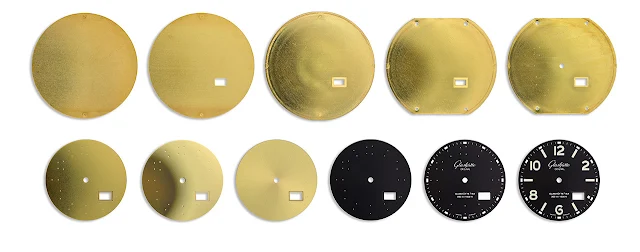

Once the dial design is finalized, blanks are punched from the selected material, adhering to tolerances within a few hundredths of a millimeter. Positioning cams are then precisely added to ensure exact alignment throughout the entire production sequence.

Precision machining and assembly

Computer-controlled milling is employed to cut openings for various complications, such as date displays, sub-dials, and moon phase indications. Precise depth control is essential here, particularly when layered components must remain perfectly level with the main surface.

Following this, the blank is trimmed to its final diameter, and the positioning cams are removed. Dial feet are then securely attached to the underside either by friction fitting or laser welding, depending on the design. This ensures secure and accurate mounting onto the movement during final assembly.

Surface treatments and finishing

The surface finish is meticulously determined by the dial’s design specifications. For galvanised dials, metal layers such as nickel, gold, or rhodium are deposited by electrochemical processes. Bath composition, temperature, and current are carefully regulated to achieve uniform colouration, whether it be silver, black, anthracite, or blue.

For lacquered dials, colour pigments are applied by precision spraying. Multiple coats are cured under strictly controlled conditions to create a smooth, even surface. The choice between a matte or high-gloss finish depends on both the specific lacquer composition and the subsequent polishing method.

All surface treatments are carried out within pristine cleanroom environments. Controlled air filtration and dust-lock systems help maintain the rigorous standards required for flawless finishes.

Once the dials have been rinsed in clear water and dried they are ready for the application of numerals, indexes, the logo, lettering and additional details.

Pad printing techniques

Dial printing is performed using a sophisticated pad transfer method, which utilises silicone pads and intricately engraved cliché plates. Each colour is applied separately with registration tolerances meticulously kept below 20 microns.

For raised motifs, the ink formulation is precisely adjusted to allow for successive layering. This technique produces a consistent three-dimensional relief. The printed layers are subsequently cured by UV light or oven drying, depending on the materials used.

Application of markers and lume

Appliques, whether polished or brushed, are manufactured separately and applied by hand with utmost precision. They are fixed to the dial either with specialised adhesive or by mechanical attachment, based on the specific structural design.

Luminous elements are filled with Super-LumiNova. Application involves a controlled sequence of masking, filling, and leveling to ensure uniform luminosity. The compound is then cured under specific light and temperature conditions to guarantee reliable luminescence.

Inspection and quality assurance

Each dial passes through as many as 75 individual process steps. Intermediate checks are performed after all critical operations, including machining, finishing, printing, and assembly.

Dimensions are verified using optical comparators and precision measurement tools. Surface cleanliness is exhaustively examined under high magnification and directional lighting to detect any imperfections. Once complete, the flawless dials are vacuum-sealed and carefully prepared for integration into the watch assembly line.

Crafted details and decorative work

The excellence of a dial is ultimately determined by the craftsmanship evident in its details. This is observed in elements such as the precise light play of a finely brushed sunray finish, the distinctive surface created by traditional silver plating by friction, the nuanced optical depth of mother-of-pearl, or the intricate functionality of a moon phase display. Each feature is the result of dedicated artistry and rigorous technical execution.

Silver plating by friction: On certain engraved dials, Glashütte Original employs silver friction plating. This manual process involves rubbing a silver-salt paste into the metal surface to create a fine-grained, matte finish. Consistent results depend crucially on the correct pressure, motion, and composition of the compound.

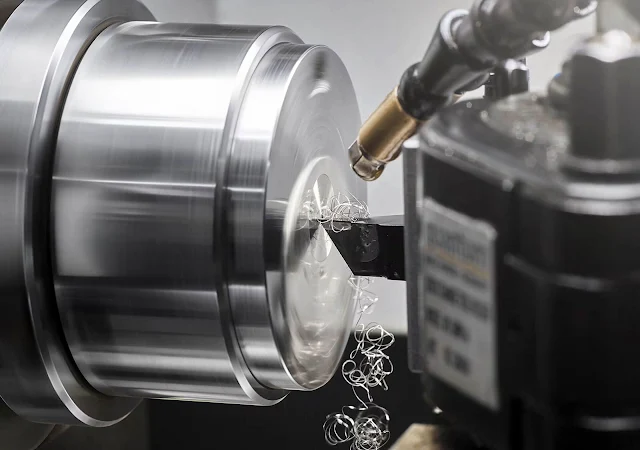

Circular graining: This radial surface treatment, also known as spiral or vinyl finish, is applied using a precision lathe. The tool removes minute amounts of material in a continuous motion, producing a captivating texture that enhances light play and legibility. This finish is frequently used for sub-dials and indicator rings.

Sunray brushing: To create a dynamic sunray finish, the dial is rotated against a rotating brush coated with fine abrasives. This technique forms precise radial lines that reflect light dynamically. The delicate texture is carefully preserved through galvanization, which seals the surface without reducing contrast.

Mother-of-pearl processing: Mother-of-pearl is a natural material that demands extremely delicate handling. Each wafer is milled to a thickness below 0.4 millimeters and securely bonded to a metal support for structural stability. Tinted lacquers are sometimes applied to the reverse side, creating an optical depth through light interference.

Moon disc engraving: The starry sky motif for moon phases begins with a coated metal disc, onto which the pattern is printed in lacquer using a resist technique. The exposed areas are then sandblasted and subsequently galvanised. Finally, the moon figures are meticulously engraved with a diamond bur and polished to achieve a defined contour and reflective surface.

Panorama Date construction: The proprietary Panorama Date system utilizes two concentric discs mounted on the same plane, cleverly eliminating the need for a central divider. The discs are precisely synchronized to transition smoothly, with manufacturing tolerances held to an impressive within 10 microns.

Glashütte Original’s in-house dial production ensures full control over every aspect of design, functionality, and long-term stability. From raw material to finished component, every stage reflects the brand’s commitment to precision, vertical integration, and enduring quality in fine watchmaking. glashuette-original.com

Suggested reading:

COMMENTS